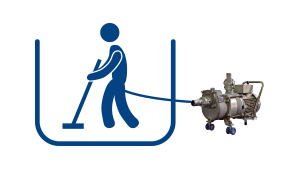

Fermentation tank cleaning

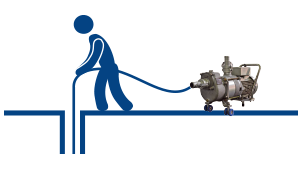

crab restaurant

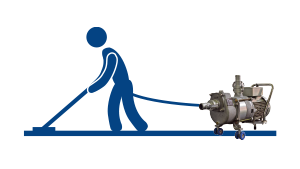

Water tank cleaning

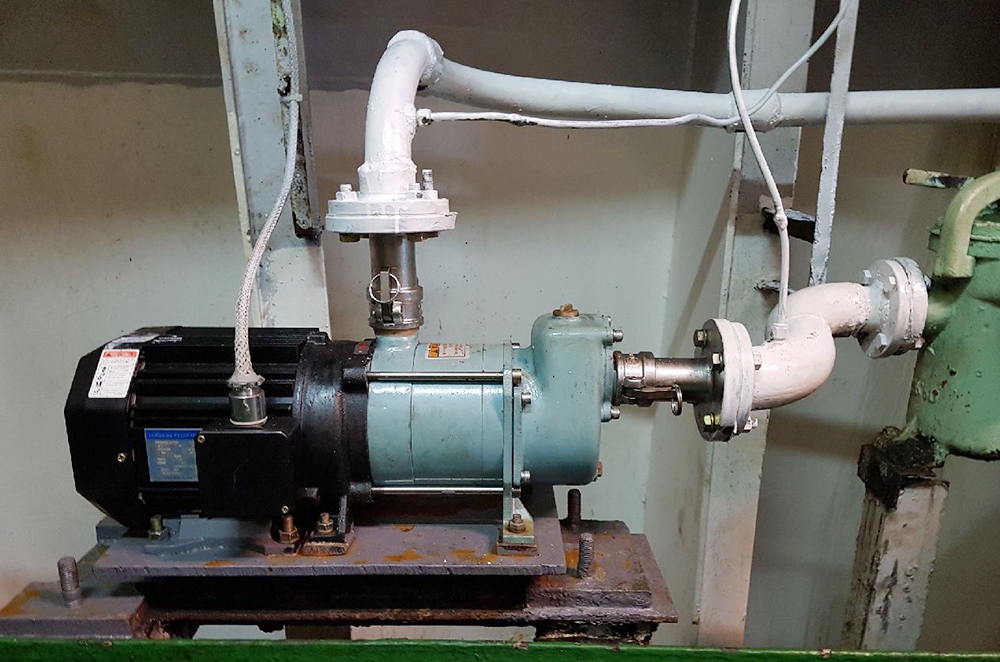

MCT, CNC coolant transfer

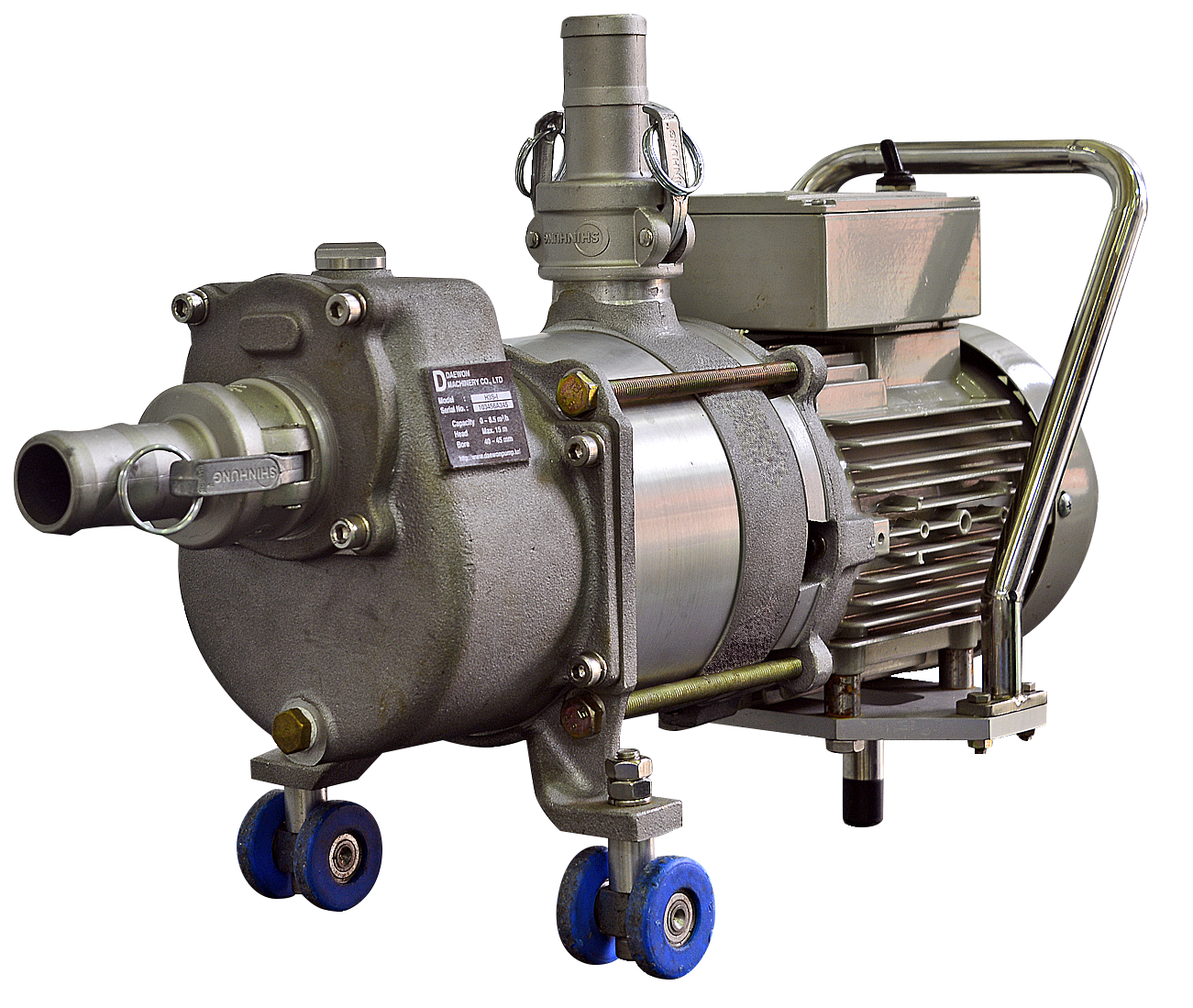

- Powerful suction with both vacuum pump and fluid transfer sucks and transports the fluid.

- Possible to suck and transport from a place far from the source

- Can be installed and used in a place away from or away from a hazardous area

- Unlike general pumps that cannot be pumped when air is inhaled, water and air are transported together even when air enters

- Self-absorption function up to 8m maximum suction height (vertical height for suction) enables suction in deep places

- If necessary, a crusher can be installed to crush and transport solids.

| Daewon Method | Existing Method | Remarks | ||

|---|---|---|---|---|

| 1 | Convenience |

- Zero residue - Switch on 2~5 seconds pumping - One-touch piping connection - Easy to move and transport - Compact size, light weight |

- Insufficient removal of residue / rework - Inconvenient hose attachment and detachment - Long removal time |

- Simultaneous suction of water and air |

| 2 | Productivity |

- 5 seconds / 1 tank - 30 tanks / day = 2 minutes 30 seconds |

- 5 minutes / 1 tank - 30 tanks / day = 2.5 hours |

- Reduced residue removal time by more than 10 times - Save more than 2 hours/day |

| 3 | Economic feasibility |

Minimum Wage: ₩8,720 (2 persons ₩17,440) 8,720 * 0.5 hours/day 8,720 * 30 = ₩261,600 |

Minimum Wage: ₩8,720 (2 persons ₩17,440) 17,440 * 2.5 hours/day 43,600 * 30 = 1,308,000 |

- Reduction of more than 1 million won per month - Annual savings of more than 12 million won - Less than 2 months of investment payback period |

| Monthly fee | Month required ₩261,600 | Month required ₩1,308,000 | ||

Effect of shortening fermentation tank cleaning time

| Conventional | H3S | |

|---|---|---|

| Cleaning time (1 tank) | 10 minutes | 1minutes |

| Total time (25 tanks) | 250 minutes | 25 minutes |

- Tank cleaning time and preparation time reduced by 10 times or more

- Easy to clean due to portability and simplicity

- Simultaneous transport of water and air with strong suction power

- Safe because you do not need to go inside directly

- Labor cost reduction and productivity improvement possible

Fermentation tank cleaning and use

| NO | Client | Usage |

|---|---|---|

| 1 | PANASIA | Close type Scrubber의 Slurry Transfer Pump (Magnesium transfer pump) |

| 2 | DH Shipbuilding, Samkwang Shipbuilding | Ship bilge, Sludge pump |

| 3 | Korea Shipping, Polaris | Ship bilge pump |

| 4 | Shipbuilder | Vacuum cleaning of toilets |

| 5 | Korea East-West Power | Suction and removal of underground dirt from the cooling water discharge lock gate |

| 6 | raw rice wine factory | Suction and removal of residues |

| 7 | DAEGAEMANCHAN(crab restorant) | Seawater supply after seawater suction far from the source |

| 8 | Jinil C&C Ready-mixed Concrete | Suction and removal of floor residues from large rooftop water tanks |

| 9 | Dongwon Engineering | Suction and removal of power plant cooling water intake part jellyfish |

| 10 | General branch offices | Installation far from river water, suction and supply of river water, suction and removal of residuals from the bottom of the water tank as a substitute for submersible pump |

| 11 | Incheon Songdo Central Park Park | Suction and removal of Lake Scum |

| 12 | Hyundai WIA | Suction and transfer of machining cutting oil for machine tools such as MCT, CNC, etc. |